Nawigacja: English

Acoustic Emission Diagnostic Poland Ltd. specialized in conducting diagnostic research of devices, technical objects and building structures, monitoring and reporting the results of the non-distructive tests based on the Acoustic Emission method (Acoustic Emission Testing – AET).

Acoustic Emission Diagnostic Poland Ltd . offers its customers innovative solutions in acoustic emission (NDT-AE) testing services, including consulting and training programs to ensure that Acoustic Emission Diagnostic Poland Ltd. clients reap maximum benefits. Services are performed by International standards ISO, european EN, national PN, GOST, GOST-R and other technical and producers standards like a API, ASTN, CEN, CENELEC, EWGAE. We have a team based on the best of technical experts with 3 level of AE. certified operators providing experienced AE Inspection. Acoustic Emission Diagnostic Poland Ltd., uses portable computers and devices based systems in conjunction with the latest digital technology software available to provide unsurpassed expertise in the nondestructive testing industry.

The main fields of application testing and services NDT-AE:

– pressure vessels (also the underground) ,

– spherical vessels,

– tank storages,

– pipelines,

– water dams,

– aircrafts,

– marines,

– concretes,

– space frame constructions (bogies, drilling platforms, mining towers),

– composite materials and constructions,

– cranes (made in metal or composites technologies),

– LNG, LPG terminals,

– rail industry,

– petrochemical and chemical industry,

– other,

Acoustic Emission Diagnostic Poland Ltd. specialized in design, installation, management and service of innovative hidden security systems of buildings, technical infarstructure, devices and open areas using method based upon seismic technology and satellite working position sensor via GPS and cartogfafical programs.

If you want to know more about seismic security system of „BARIERA”, go to www.bariera.pl or www.bariera.com.pl

Remember „Your safety, first of all”

Non-Destructice Testing (non-intrusive) NDT with respect to pipelines and storage tanks:

– “zero” pre-use testing of objects,

– initial (diagtnostic) testing of a pipeline with the use of the trenchles technology,

– technical condition of the object without draining it of the medium or exclusion from use (pits, corrosion, cracks, microcracks, escapes, interspaces, necking downs etc.) underground, above-ground and underwater objects – supervised and non-supervised objects in accordance with the Office of Technical Inspection,

– precise localisation of leakages, escapes (in sudden cases the possibility of express localisation of the escape of a petrochemical product), cracks, areas of stress concentration, anomalies in the material structure,

– virtual, precise marking of the outline and the foundation of the object (designation in accordance with the satellite coordinates together with the virtual depth of the foundation),

– positioning the virtual parameters of the outline and charactersitic places, including the dangerous and damaged ones, on the electronic map according to GPS,

– assessment of the condition of the pipeline insulation,

– marking the pleces of defects and anomalies on the pipeline insulation structure,

– marking the illegal connections to transmission pipelines,

– verification of the type of corrosion,

– general diagnostic tests of the broad character (including underwater objects),

– diagnostic tests of the walls and the bottom of the storage tank – without draining or idle times, preparatory and implementation works outside the object.

REMEBER

– No Need to Empty or Clean the Tank

– 100% Floor Inspection

– Verified Reliability

– Inspection and Evaluation of Annular Ring

– Immediate Results

– Rapid testing: 50 meter tank in one day

– Identify tanks that need inspection and repair,

– Leave good tanks on-line and save shut-down and cleaning,

System of comprehensive technical KDM monitoring (pipelines, big storage tanks)

– efficiency of an appliance/object,

– productivity of an appliance/object,

– working temperature of an appliance/object,

– working pressure of an appliance/object,

– sealing of an appliance/object,

– technical condition of an appliance/object,

– flow speed, quantity/condition of a petrochemical product,

– level of deformation of an appliance/object,

– parameters of the ground,

– level of deposits, sludges,

– petrochmical and refinery instalation automation,

– storage tank park technological automation,

– and other depending on the needs of the investor.

Seismic Protection System “BARRIER” (pipelines, big storage tanks, fuel bases)

Comprehensive, wireless and independent system of hidden protection of objects against:

– approaching by foot (a man, a group of people),

– driving near (machine, vehicle, car),

– efforts to connect to the pipeline illegally,

– digging and underground passages,

– efforts to violate or break the communication,

– efforts to sabotage and bypass the system as well as the change of the record of events,

– registration, verification and signalling of approaching unauthorised objects,

– registration, verification and signalling of approaching unauthorised objects with dangerous tools such as cutting devices, gavelocks, grinders, shears, cold weapons, firearms,

– transfer of information and securing objects at the distance of several hundred kilometers,

– satellite positioning (GPS),

– registration of the picture record (video) day/night, thermovision,

– differentiation of dangerous and safe events,

– openness of the system.

QUALITY POLICY

The company AED Polska Spółka z o. o. acts in accordance with reliability, honesty and professionalism. The process of constant improvement is the basis of our development.

- Our aim is to render individualized services, which not only will meet any criteria of effective regulations but also will exceed the requirements and expectations of our clients. We act on a basis of public rules which exactly specify the basic principles of the services rendered by AED Polska Sp. z o. o.

- The pursuit of high quality assurance concerns both the Company’s employees and external subcontractors cooperating with us.

- All employees and associates of the Company are responsible for the quality of the carried out research, the worked out results and the reports.

- We cooperate only with highly qulified suppliers of goods and services, who are properly experienced and have consolidated knowledge in the aproppriate field, supported by proper certificates, in order to render our clients the services at the possibly highest quality level.

- Safety and security of the information we are entrusted with by a client is an integral part of the process of comprehensive rendering of the services.

- We constantly encourage and motivate our employees and associates to a creative and efficient cooperation in order to improve the quality of our services and the qualifications.

As The President of the Board I declare complete commitment in order to provide resources, the systematic development of the Company business and of the implemented quality system based on the international Norm ISO 9001:2008.

Andrzej Kaźmierczak

The President of the Board AED Polska Spółka z o. o.

Warsaw, 6th of January 2009

Everything what we do – we do with Policy of International Standards ISO 9001:2008

Best regards

CEO and Team of AED Poland Ltd

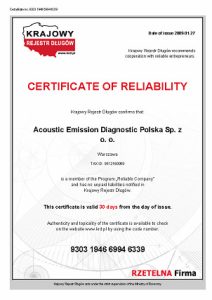

Our certificates and recognition

AED Polad Ltd.

40 Jana Rosoła Street

02-792 Warsaw

Poland

Zone – Central Europe + 1 GMT

Najnowsze wiadomości

Laboratorium Acoustic Emission Diagnostic Polska Sp. z o. o. z dniem 30 marca 2018 roku uzyskało Świadectwo Uznania Laboratorium nadane przez Urząd Dozoru Technicznego do prowadzenia badań laboratoryjnych pod numerem:

LBU-242/27-18 zgodnie z PN-EN ISO/IEC 17025:2005.

Już dzisiaj możesz wykonać kompleksową diagnostykę urządzenia technicznego dozorowanego metodą Emisji Akustycznej

– bez potrzeby opróżniania urządzenia,

– bez potrzeby wstrzymywania cyklu pracy,

– bez potrzeby inspekcji wewnętrznej ,

– bez potrzeby rozizolowywania urządzenia,

– bez potrzeby utylizacji magazynowanego medium,

Wybierz AED Polska Sp. z o. o. a doradzimy i opracujemy program badań technicznych pod kątem konkretnego urządzenia, zweryfikujemy niezbędne wymagania stawiane przez Urząd Dozoru Technicznego, dzięki czemu Tobie pozostanie bezpieczne eksploatowanie urządzenia w ramach Utrzymania Ruchu oraz zaoszczędzony czas oraz środki finansowe.

Prześlij na adres e-mail: aed@aed-polska.pl swoje dane kontaktowe oraz zagadnienie którym jesteś zainteresowany – gwarantujemy że odpowiedni dział AED Polska Sp. z o. o. skontaktuje się z Tobą w ciągu 24 godzin, celem omówienia sprawy.

Nasze nagrody i wyróżnienia:

Acoustic Emission Diagnostic Polska Sp. z o.o.

posiada wdrożony

Zintegrowany System Zarządznia

Jakością wg. ISO 9001/ISO 14001/ISO 45001